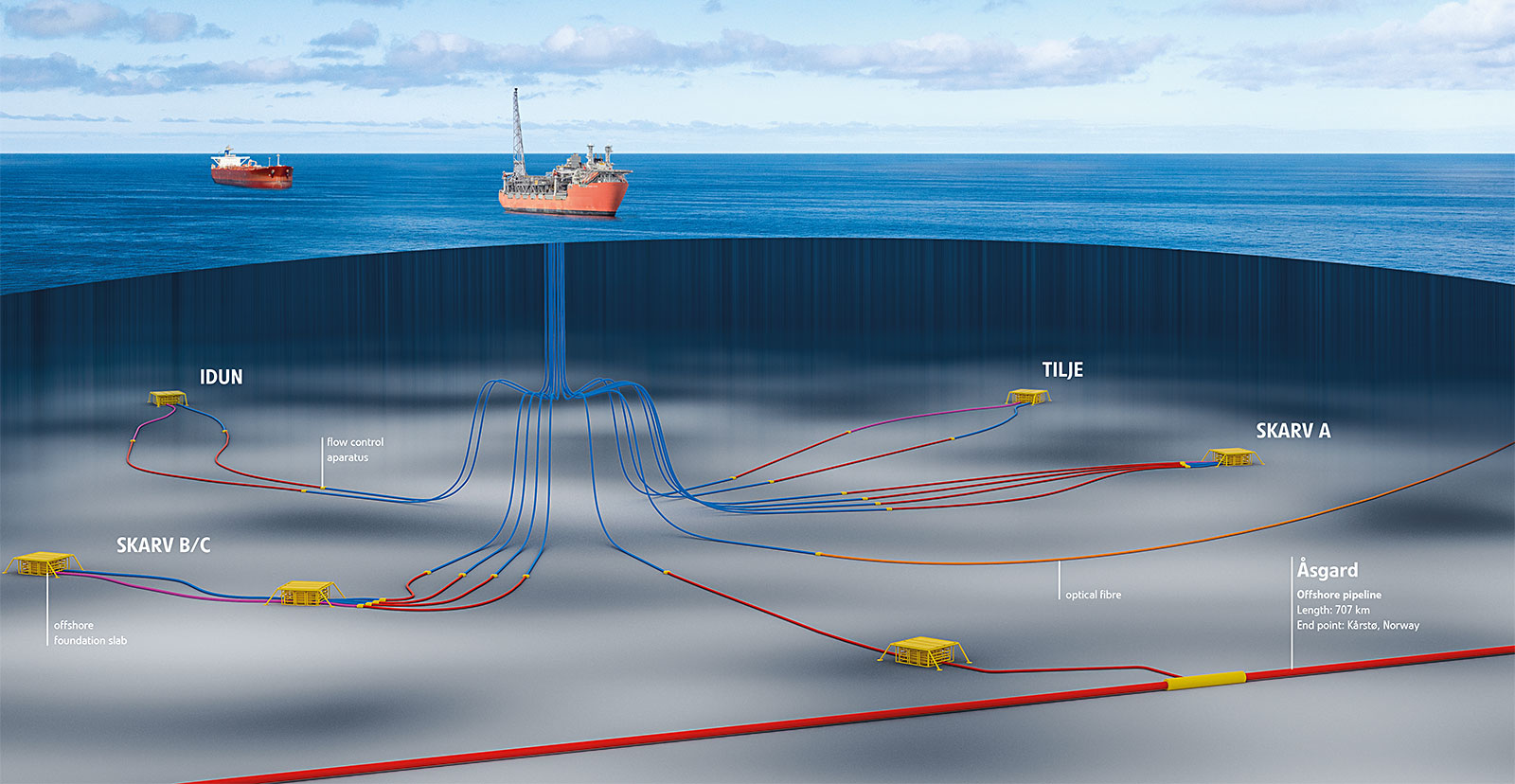

Floating production, storage and offloading unit – a floating platform designed to extract, pre-clean, store, and reload oil and gas from offshore fields. The FPSO extracts oil and gas from the production wells. The gas is purified and then transported via an offshore pipeline. Crude oil is stored in the unit’s internal storage after pre-cleaning.

History

Initially, oil and gas in the offshore mining industry was extracted from fields lying shallow under the water surface – at a level of up to at water depths not more than 50 meters.

When shallow oil and gas fields were exploited, the oil and gas were transported to land by pipeline. This method has become economically inefficient in the case of production from offshore fields at water depths of several hundred meters and at distances of as much as 100 kilometers from the shore. It was technically difficult and unprofitable to lay a pipeline of this length several hundred metres below sea level. Initially, oil and gas were received by feeder tankers on an ongoing basis, which, however, could not be berthed in the immediate vicinity of the production platform for safety and cost reasons.

Storage of oil pending its reception was solved in such a way that several tankers, called FSO (floating storage and offload units), were permanently anchored at a suitable distance from the platform. They were connected to the production platform by pipelines and functioned as temporary tanks for oil, which was pumped to the so-called shuttle tanker.

Over time, this technology has been improved by installing oil and gas purification equipment in the FSOs and connecting these units directly to seabed intakes. The FPSO units used by PGNiG Upstream Norway were created in this way.